Definition of Life Cycle Assessment

A Life Cycle Assessment (LCA) is a quantitative methodology that measures the environmental impact of a product over the course of its lifetime.

What is Life Cycle Assessment?

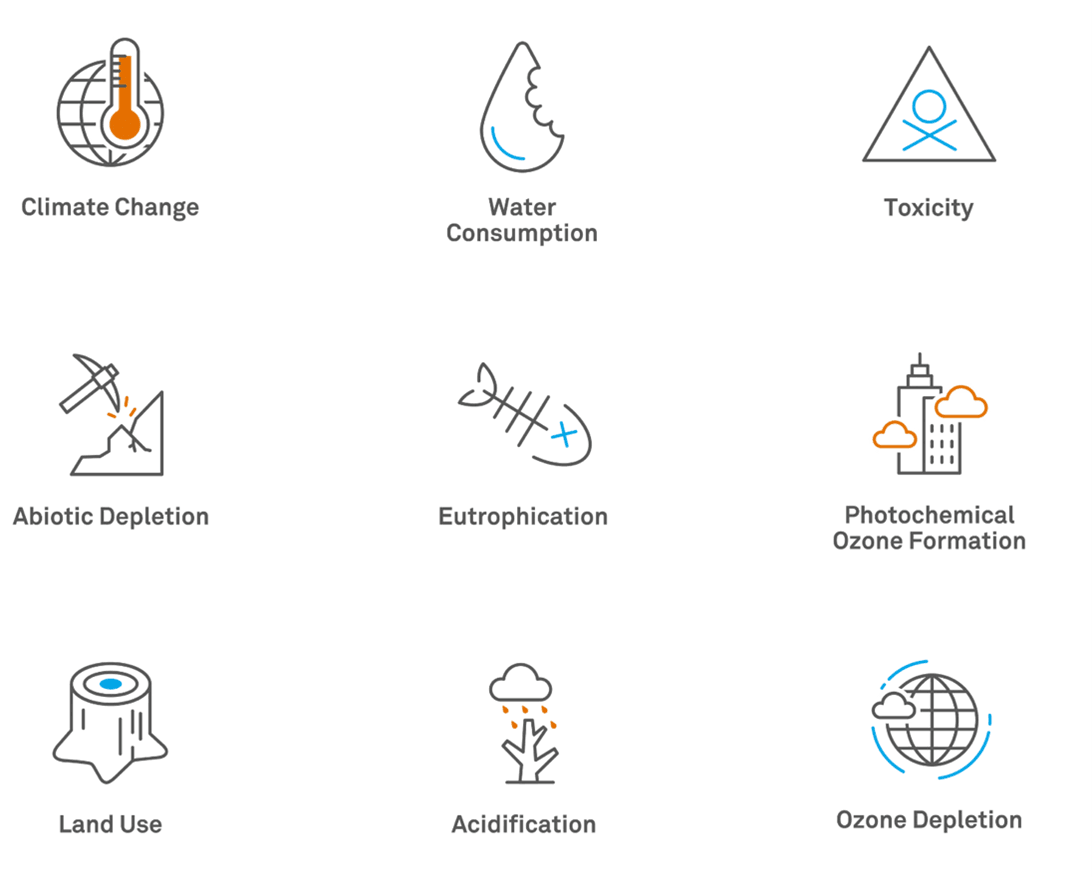

LCA methodology measures a product’s environmental impact at every stage of its life – from raw material extraction to manufacturing, end use and disposal. This comprehensive assessment doesn’t just focus on carbon emissions: in fact, there are nine impact categories in total:

Globally-recognised procedures for conducting LCAs are included in the environmental standards of the International Organisation for Standardisation (ISO). ISO 14040 and ISO 14044 are particularly relevant to LCAs, as well as ISO 14067 which outlines the requirements for carbon footprint quantification.

What are the benefits of Life Cycle Assessment?

Manufacturers around the world are under pressure to make their processes more responsible – and they need a complete picture of their products’ environmental impact in order to do this. LCA is a holistic methodology: it avoids optimising one environmental factor without considering the effects on other indicators.

And as well as being holistic, it’s standardised. This allows decision makers to compare two different products with confidence, then determine which one has a lower impact on the environment.

Ultimately, the better we understand our impact, the better we can reduce it, and thereby meet our ESG targets.

What are the challenges associated with Life Cycle Assessment?

Life Cycle Assessments are time consuming. In Stahl’s case we need to accurately account for the complexity and variability of chemical processes, including the choice of chemical raw materials.

LCA is a decision-making tool, but it can be challenging because of different priorities and varying levels of expertise. To maintain data reliability, a company using LCA methodology must engage closely with its stakeholders, especially in its supply chain, to achieve consistent results.

What is the future of Life Cycle Assessment?

As more organisations focus on their contribution to environment and society, we can expect to see LCAs being deployed at earlier stages of the manufacturing process. After all, it’s easier to design a sustainable product from scratch than it is to make an existing product compliant.

In the next decade, we expect LCAs to become more automated, and machine learning technology, like AI, will contribute to the collection of data more efficiently, and to realize real-time calculations on our environmental footprint, supporting us in our purpose: Touching lives, for a better world.

Learn more about how Stahl does LCA.