Crosslinkers with top-class performance and a lower environmental impact

Crosslinking is widely practiced in the coating industry as a means to improve coating performance on wear, abrasion, chemical & stain resistance, toughness and blocking properties. As an addition to coating formulations, they provide a wide range of additional possibilities. Our carbodiimide crosslinkers (CDI) provide a sustainable, yet high-performance alternative for formulators in the paint and coating industry, looking to reduce their environmental footprint with full performance qualities. With RelcaLink® carbodiimide crosslinkers, Stahl offers innovative solutions that enable customers to enhance the environmental profile of their products and processes, ultimately contributing to the reduction of scope 3 emissions.

Carbodiimide Crosslinkers environmentally-friendly enhancer for coating qualities

Crosslinking works by connecting the polymers through reactive chemistry, thus strengthening the network of a specific coating. But stabilizing the polymer strains has disadvantages when it comes to flexible materials, as coating properties then may be reduced in elongation, strength and flexibility. A high level of crosslinking is suitable for rigid materials, but flexible materials require a level of malleability suited for waterborne systems to maintain their desired properties. Compared to traditional crosslinkers, such as aziridine, isocyanates, and melamines, polycarbodiimide crosslinkers have a number of advantages. Polycarbodiimides are much less sensitive to the presence of water and able to achieve long pot-life. Due to the high reactivity, curing with CDI type crosslinkers can be done at room temperature and under typical oven conditions used for drying of applied coatings.

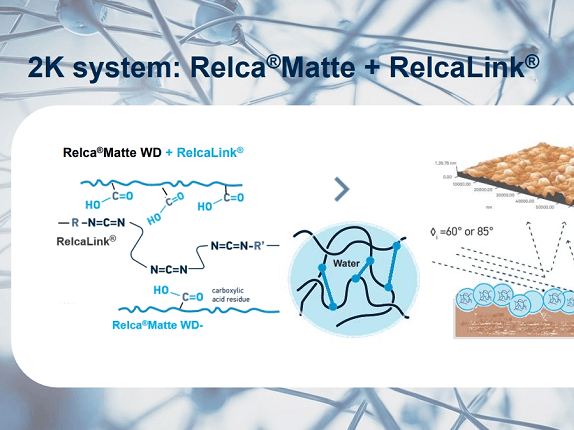

Suitable for 2K Coating systems

In addition to standard CDI crosslinker chemistry, we offer a range of crosslinkers with 2-stage reactivity. A second type of reactive group is attached to the polycarbodiimide in this range, so upon curing this crosslinker not only reacts to the -COOH groups in the polymer chains. These reactive groups react to form an even denser network structure. To further build on the success of our polycarbodiimide crosslinkers, we have upgraded our technologies to provided VOC-free new CDI versions with extreme long pot-life.

Webinar: New carboxylic-functional ultramatte binder for 2K systems with carbodiimide for high performance coatings

Low VOC & label free alternative

Optimised -COOH functionality

Chemical & mechanical resistances

Transparency & self-healing

Download webinar and presentation

Key Benefits of Carbodiimide Crosslinkers

Carbodiimide crosslinkers offer various advantages for production of coatings for both flexible and hard materials.

Key benefits:

Friendly labeled

Improved pot life

Not moisture sensitive

Fast curing speed upon drying

Improved chemical & stain resistance

Low viscosity & easy to use

VOC-free

Improved adhesion and chemical resistance

Increased abrasion resistance, strength and hardness

CONTACT US